How much do you know about silicone sealants?

Silicone adhesive is a high-grade adhesive sealing material with elastic bonding function, which is prepared by compounding, mixing, homogenizing and other processes, based on terminal hydroxyl siloxane polymer and multifunctional siloxane crosslinker, and adding auxiliary materials such as plasticizer and reinforcing agent. It is cured at room temperature (RTV) and has elastic bonding function.

It is in the form of ointment, and solidifies into a tough rubber-like solid material after contact with air. It is mainly divided into deacetic acid type, dealcohol type, deamino type, and deacrylic acid type. Silicone adhesive is commonly known as glass adhesive because it is often used for bonding and sealing of glass.

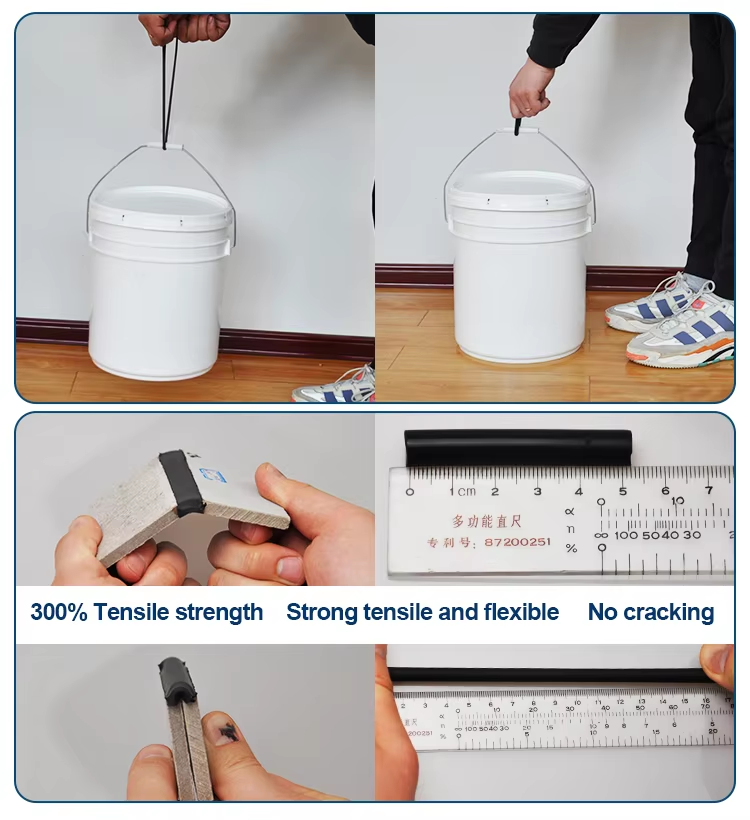

Silicone adhesive has strong adhesion, high tensile strength, weather resistance, high and low temperature resistance and other properties. Silicone adhesive is divided into single and double component packaging, which is easy to use. Therefore, it occupies an important position in the market of building waterproofing, door and window and curtain wall structure glass assembly and building decoration.

01 Classification of silicone adhesive

Silicone adhesive is divided into neutral weather-resistant adhesive and silicone structural adhesive according to its use

Neutral weather-resistant sealant

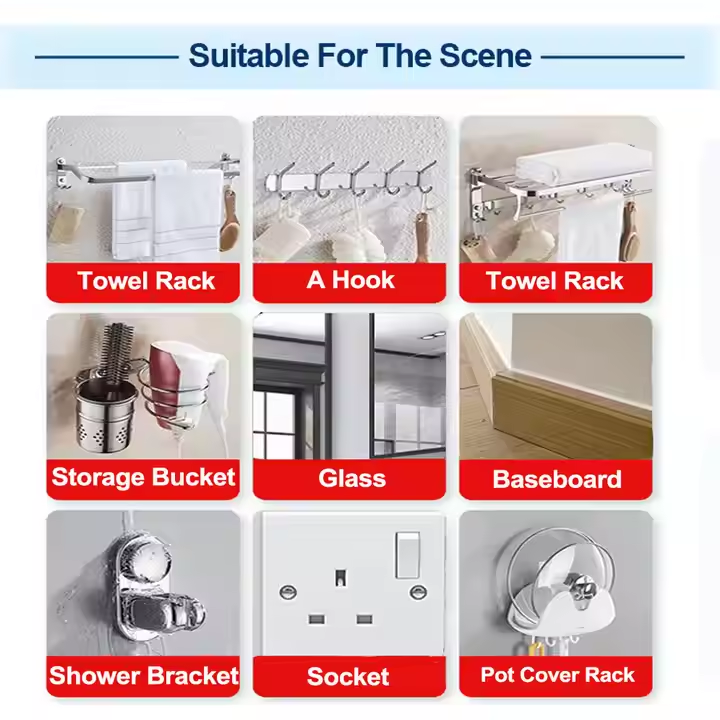

1. Suitable for weather-resistant sealing of various curtain walls, such as glass curtain walls, aluminum-plastic panel curtain walls, and stone dry hanging weather-resistant sealing.

2. Sealing joints between various materials, such as metal, glass, aluminum, tiles, marble, concrete, masonry, steel, wood, etc.

Door and window sealing

Bathroom edge sealing

Pool edge sealing

Baseboard edge sealing

Silicone structural sealant

1. Mainly used for structural or non-structural bonding assembly between metal and glass of glass curtain walls.

Glass curtain wall construction

Sunroom

Glass balcony

2. Structural bonding and sealing of hollow glass.

Construction precautions for silicone adhesive

1. Thoroughly remove all loose particles and dust to ensure that the construction surface is clean, dry, and free of grease and surface dirt such as release agents, maintenance films, and hydrophobic agents.

2. Construction should be carried out in a clean environment with a temperature of 4~40℃ and a relative humidity of 40%~80%, and construction should be stopped in rainy and snowy weather.

3. In order to prevent the expansion of the joint from damaging the sealing adhesive, the joint should be filled with a suitable backing material, and the width of the backing material should be greater than 25% of the joint width to control the thickness of the sealant.

4. A bevel should be cut at the outer mouth of the sealant can, and then an extrusion gun should be installed to squeeze the sealant into the pressure surface of the joint. The thickness and width of the sealant should be uniform and consistent, meeting the sealing requirements.

5. If the sealant is not completely cured within 48 hours after application, the sealing joint is not allowed to have a large displacement, otherwise it will affect the sealing effect.